NDT stands for non-destructive testing. In other words it is a way of testing without destroying. This means that the component- the casting, weld or forging, can continue to be used and that the non destructive testing method has done no harm in today’s world where new materials are being developed, older materials and bonding methods are being subjected to higher pressures and loads, NDT ensures that materials can continue to operate to their highest capacity with the assurance that they will not fail within predetermined time limits.

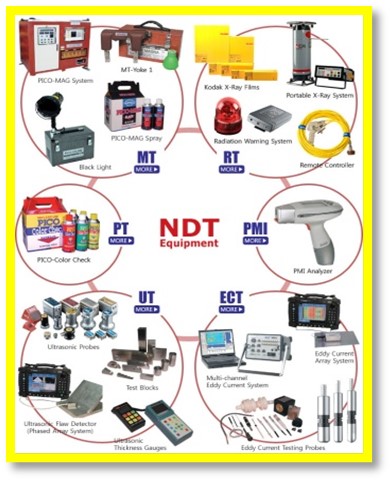

NDT is used across industries such as oil and gas sector, petrochemicals, nuclear, power generation, and wind mill, general Fabrication (pressure vessel& boilers, tank manufacturing) to name a few. It is a crucial aspect of quality control and ultimately health and safety. Common NDT methods include visual testing, penetrant testing, magnetic particle testing, radiographic testing and ultrasonic testing, radiographic film interpretation, and each have their advantages and disadvantages. With advancements in digital control and imaging, other techniques have been developed including phased array ultrasonic testing, time of flight diffraction. We are trusted by industry to deliver high quality NDT training.

SREE BALAJI TECHNICAL INSPECTION SERVICES(SBTIS) – NDT Training and Welding Inspection Institute in Trichy.

@2022 All Rights Reserved By SBTIS. Designed by Samsaj Info Tech