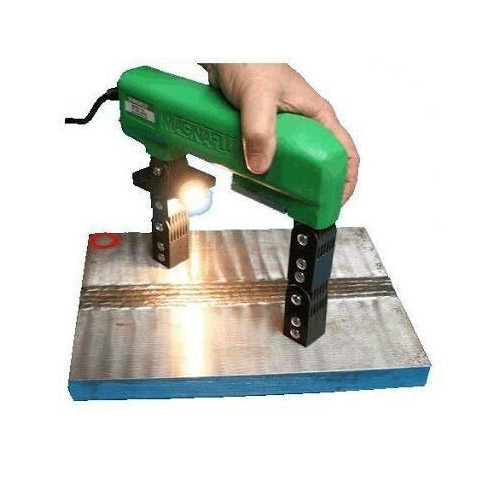

A nondestructive testing technique for finding flaws is magnetic particle inspection. Part surface preparation is not as important for MPI as it is for some other NDT methods, which makes it quick and relatively simple to apply. Due to these qualities, MPI is one of the nondestructive testing techniques that is most frequently used.

To find faults in components, MPI uses magnetic fields and tiny magnetic particles, such iron filings. A ferromagnetic substance, such as iron, nickel, cobalt, or certain of their alloys, must be used to make the component being inspected in order for it to be inspectable. Materials that can be magnetised to a degree that makes the inspection effective are ferromagnetic materials. A range of product shapes, including castings, forgings, and elements, are inspected using this technique. Magnetic particle inspection is used across a wide range of sectors to assess a component’s usability. The structural steel, automotive, petrochemical, power generation, and aerospace industries, to name a few, are some examples of sectors that use magnetic particle inspection. Another area where magnetic particle inspection may be employed is underwater inspection to test things like offshore infrastructure and underwater pipelines.

All NDT employees, mechanical engineers, inspectors, and technicians involved in or in charge of weld inspection, inspection of castings and forgings during fabrication, or in-service inspection are intended for this course. You will learn about magnetic lines of force, testing procedures, reading test results, demagnetization, hands-on activities, and report writing instruction.

SREE BALAJI TECHNICAL INSPECTION SERVICES(SBTIS) – NDT Training and Welding Inspection Institute in Trichy.

@2022 All Rights Reserved By SBTIS. Designed by Samsaj Info Tech